Understanding “Circulating Fluidized Bed Combustion (CFBC)”

€2,330.00 excl. VAT

Instructor

Frans van Dijen

Frans van Dijen is a senior expert in combustion and emissions in power stations and co-generation units. He has experience with design, efficiency and troubleshooting of boilers and flue gas cleaning installations. He is also experienced with waste incineration and fuel conversion technologies. As a multidisciplinary expert within ENGIE Laborelec, his daily consulting activities in the field of combustion and emissions cover topics such as improvement and troubleshooting of combustion, conversion of boilers from coal to biomass, questions related to ash analysis and valorization, prevention or correction measures against slagging and catalyst evaluation and management for SCR denox installations.

Frameworks

Goals

This advanced course provides participants with the necessary knowledge for a detailed understanding of circulating fluidized bed combustion, its mechanisms, typical operational problems, efficiency, corrosion, materials, environmental aspects and many more.

Program

Participants will gain a general understanding of CFBC, including:

- Brief description of the CFBC

- Solid fuels, fuels pre-treatment, fuels for start-up

- Combustion

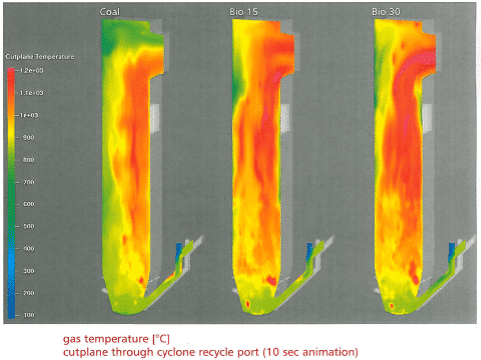

- CFBC modelling

- CFBC and suppliers

- Controls

- The boiler, boiler cleaning

- Fuel efficiency and net electrical efficiency

- Trouble shooting

- Safety issues

- Erosion prevention

- Corrosion prevention

- Refractories, other materials

- Chemistry

- Bottom ash separation, bottom ash cooling, ash recycling, bed material and recycling, bottoms

- In-bed mixing

- Dosing of fuels and additives

- Prevention of sintering of the bed

- Emissions into the air, in-situ FGD, dedicated FGD, N2O and NOX, CO, UBC, fly dust, fly ash, trace elements

- Cyclones and separation of solids

- Lessons learned

- Improving CFBC

- Particles (according to Geldart)

- Operations, starts, stops, low loads

- Special fuels, special materials and adaptations

- Fuel drying

- Risk management

- Literature

- EU policies: fly ash, bottom ash, gypsum, in-bed FGD, CCS, sustainable energy.

Target Audience

Engineers, managers with a technical background, project developers, operators, suppliers.

Practical Info

Please note that the course will only take place if the minimum number of participants is acquired.

If you would like a dedicated session for your team, or if you want information on the possible dates for this course, please get in contact at laborelecacademy@engie.com